-

Plasmatreat North America

-

Plasmatreat North America Overview

- Plasmatreat North America

- Sales Team

- Plasma as a Service

- FAQ

- Contact us

-

-

What is Plasma

-

What is Plasma Overview

- What is Plasma

- Plasma Processes

-

Plasma Surface Treatment

-

Plasma Surface Treatment Overview

- Plasma Surface Treatment

- Capability of Plasma

- Surface Activation

- Plasma Cleaning

-

Plasma Coating

-

Plasma Coating Overview

- Plasma Coating

- AntiCorr®

- PT-Print

- PT-Bond

- Functional Coating

- Plasma-SealTight®

- InMould-Plasma®

-

-

- Surface Determination

- FAQ

-

-

Industry Solutions

-

Industry Solutions Overview

- Industry Solutions

- Automotive

- Electronics

-

New Energies

-

New Energies Overview

- New Energies

- Solar Technology

- Wind Power

- Energy Efficiency

-

-

Consumer Goods

-

Consumer Goods Overview

- Consumer Goods

- Furniture

- Appliances

- Toys for Children

- Sporting goods

- Eyewear

-

-

Packaging

-

Packaging Overview

- Packaging

- Plastic Packaging

- Board and Paper

- Glass-Metal Packages

-

-

Life Sciences

-

Life Sciences Overview

- Life Sciences

- Medical Technology

- Chemistry_Biochemistry

- Plasma Medicine

- Medical Disinfection

-

- Textiles

-

Transportation

-

Transportation Overview

- Transportation

- Aerospace

- Shipbuilding

- Trucks_Trailers_Mobile Homes

- Two Wheelers_Motorcycles

-

-

-

Processes

-

Processes Overview

- Processes

- Bonding

- Printing

- Painting

- 2-Component Injection Molding

-

-

Products and Services

-

Products and Services Overview

- Products and Services

-

Openair-Plasma® Jets

-

Openair-Plasma® Jets Overview

- Openair-Plasma® Jets

- Static Jets PFW10 and PFW20

- Static Jet PFW70 and PFW100

- Rotary Jet RD1004

- Rotary Jet RD2004

- Rotary Jet RD2005

- Rotary Jet RD1010

-

- Openair-Plasma® Process Monitoring

- Openair-Plasma® Generators

-

Openair-Plasma® Systems

-

Openair-Plasma® Systems Overview

- Openair-Plasma® Systems

- Film and Foil Manufacturing

- Coil Coating

- Panel Treatment

- Profile Extrusion

- Robot Systems

-

-

Low Pressure Plasma Systems

-

Low Pressure Plasma Systems Overview

- Low Pressure Plasma Systems

- Aurora Standard

- Aurora Plus

- Aurora LC

-

-

Services for Surface Determination

-

Services for Surface Determination Overview

- Services for Surface Determination

- Test Ink Method

- Test Ink online order

- AntiCorr® Test Fluids online order

- Contact Angle Measurement - MSA

-

- Worldwide after-Sales Service

- Book a Demo

- Rent a system

- Contract Service

-

-

Company

-

Company Overview

- Company

-

About Plasmatreat

-

About Plasmatreat Overview

- About Plasmatreat

- Milestones

- Family Business

-

- Our Mission

- Innovations and Awards

-

Our Global Network

-

Our Global Network Overview

- Our Global Network

- Plasmatreat GmbH

- Plasmatreat SAS - France

- Plasmatreat North America

- Plasmatreat Trading (Shanghai) Co., Ltd.

- Plasmatreat GmbH - Turkey

- Plasmatreat Korea Ltd.

- Nihon Plasmatreat Inc. - Japan

- Plasmatreat Italia s.r.l.

- Plasmatreat Iberia S.L. - Spain

- Plasmatreat Asia Pacific Pte Ltd. - Singapore

- Plasmatreat (UK) Ltd.

- Plasmatreat Schweiz AG

-

- Research and Development

- Partners

-

-

Plasmatreat Academy

-

Plasmatreat Academy Overview

- Plasmatreat Academy

- Team

- Mission and Vision

- Facilities and Equipment

-

Online PlasmaTalks

-

Online PlasmaTalks Overview

- Online PlasmaTalks

- PlasmaTalks Archiv

-

- Seminars, Training Courses and Events

-

-

Press Area

-

Press Area Overview

- Press Area

- News and Press

-

- Trade Shows and Events

Harness the Potential of Plasma for Unrivaled Manufacturing Advancements

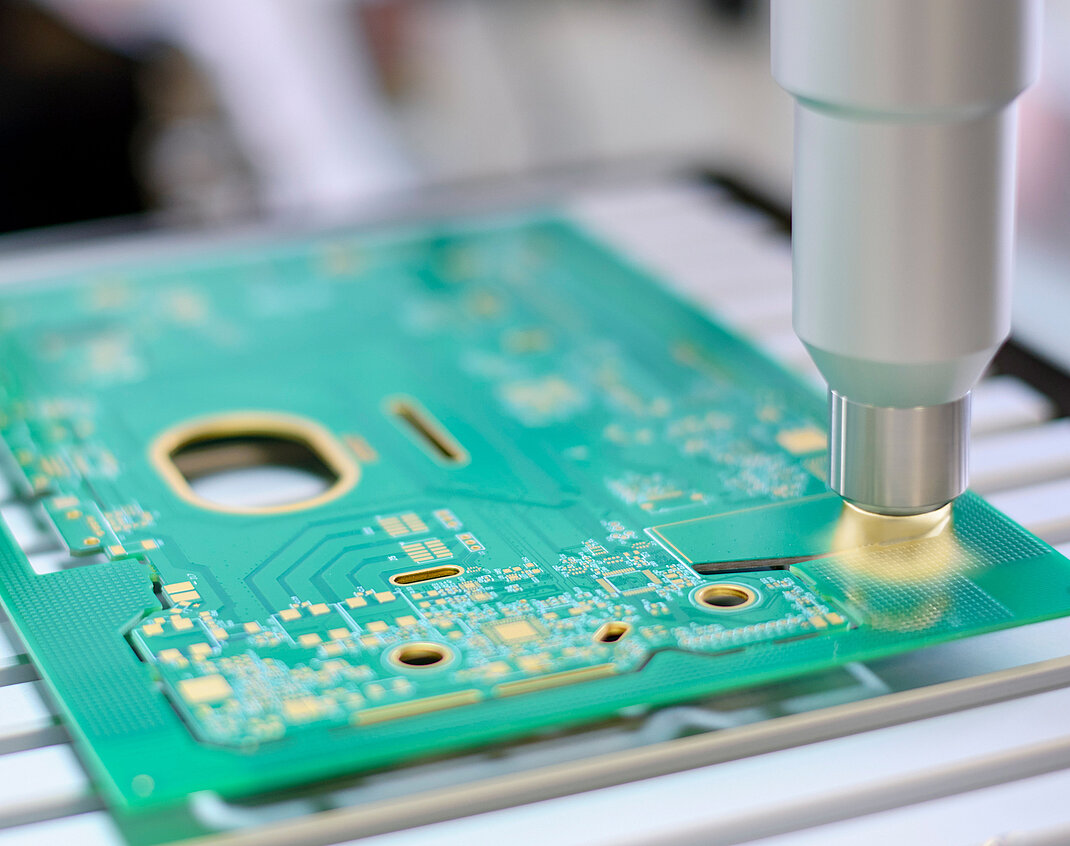

Struggling with adhesion and bonding issues, or navigating the complexities of new material combinations? Look no further – we have the solution. Our cutting-edge technology ensures precise microfine cleaning and surface activation, leading to the even distribution of adhesives for unmatched bond durability.

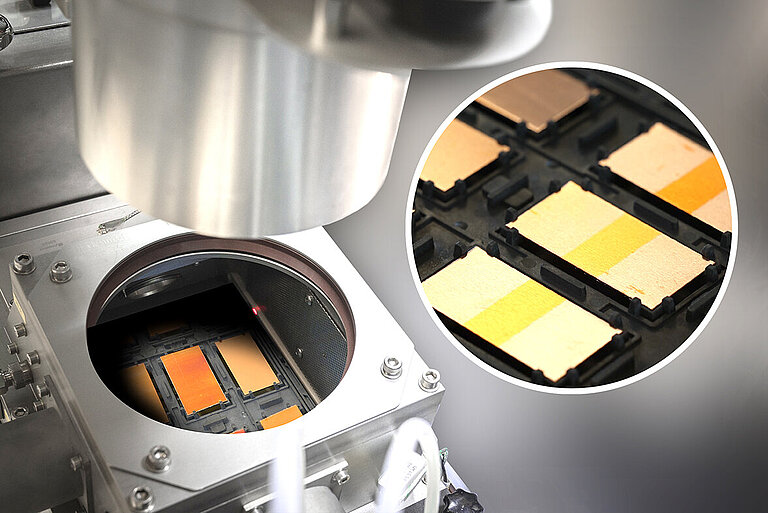

Enhance the power of plasma with our innovative PlasmaPlus® nanocoatings. From corrosion protection to enhanced barrier properties and beyond, PlasmaPlus technology opens doors to a myriad of possibilities.

Our team of seasoned experts is poised to collaborate closely with you, tackling challenges head-on and paving the path for groundbreaking products that could redefine our world. Your success is our utmost priority, and we're dedicated to equipping you with the latest advancements in plasma technology to fuel your journey towards excellence.

We love developing surface pretreatment and nanocoating solutions locally in close collaboration with our customers no matter what size and industry – from start-ups to the Fortune 500 companies in automotive, aerospace, electronics, life science, consumer goods and more.

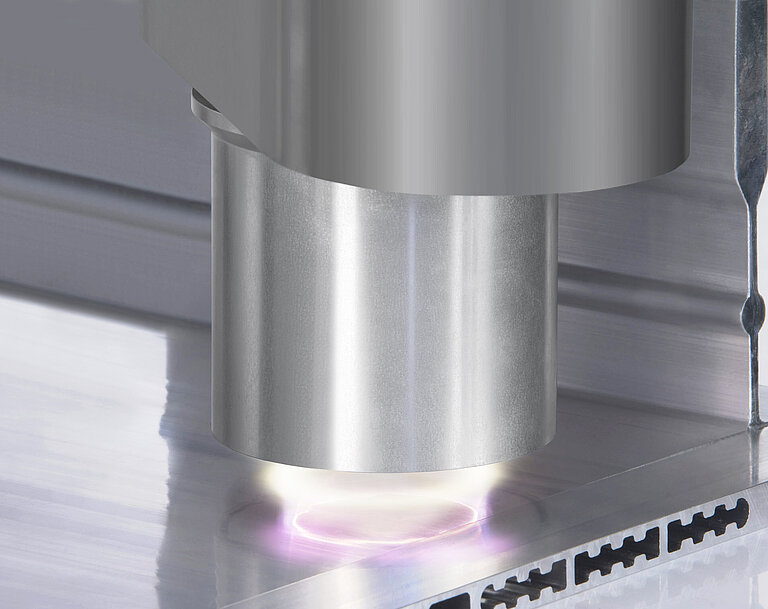

Optimizing Surfaces with Openair-Plasma®: A High-Efficiency Approach

Discover the customized efficiency of Openair-Plasma® in surface modification.

We delve into material-specific surface tension and demonstrate its impact on components through personalized dialogue and laboratory precision. Atmospheric pressure plasma proves to be an environmentally friendly solution, ideal for cleaning, activating and coating materials such as plastic, metal or glass.

Openair-Plasma® provides gentle and reliable surface preparation without chemicals, enhancing subsequent processes such as bonding or painting. Join us on the Plasma Plus® journey, where innovative solutions streamline pretreatment and offer environmentally conscious alternatives to traditional processes.

Get to know Plasmatreat North America

Our Dynamic North American Sales Force

As a leading innovator in plasma surface treatment, Plasmatreat is distinguished by its extensive North American market coverage, seamlessly serving customers from Canada to Mexico. Our strategic presence ensures robust support for customers and partners, driving innovation across the continent.

Four locations, one commitment – delivering innovation and quality

Discover excellence in the US, where innovation knows no boundaries. With strategically located facilities, we bring cutting-edge plasma surface treatment solutions closer to you.

Discover plasma live with our webinars:

The Plasmatreat Academy's webinar program proved very popular right from the start. Our first PlasmaTalks alone attracted up to 250 users. The interactive webinars are ideal for those who want to learn more about Plasmatreat and plasma technology and broaden their knowledge conveniently without having to travel. All our content is available to download worldwide and scheduled for at least two time zones.

Plasma Precision Partnering: Unleash Innovation with Our Expert Plasma as a Services (PaaS)

Are you new to plasma technology, or do you feel you lack the experience to meet the challenges of your next project?

Fear not!

Take advantage of Plasma as a Service (PaaS) and our expertise by sending your parts to our state-of-the-art lab in Hayward, CA. Our experienced team will not only treat your components with precision using state-of-the-art plasma technology, but will also manage the entire process for you.

Whether you're new to plasma or looking for expert support for a specialized project, entrust your components to us and experience the unmatched capabilities of our skilled team in Hayward.

Join our next webinar to discover the possibilities of our plasma technology

Currently no events available.

Want to see plasma live on site? Visit us at our exhibitions!

Trade Fair

06. -

10. May 2024

NPE 2024

West Building Level 2 - Expo Hall, Booth W7479

Orange County Convention Center

Orlando, Florida

Trade Fair

08. -

09. May 2024

E-Tech Europe

Booth A39-B40, hall 21

Bologna Exhibition Centre

Bologna

Italy

Trade Fair

15. -

16. May 2024

Battery Cells & Systems Expo 2024

Hall 3, booth 807

NEC Birmingham

North Ave, Marston Green,

Birmingham