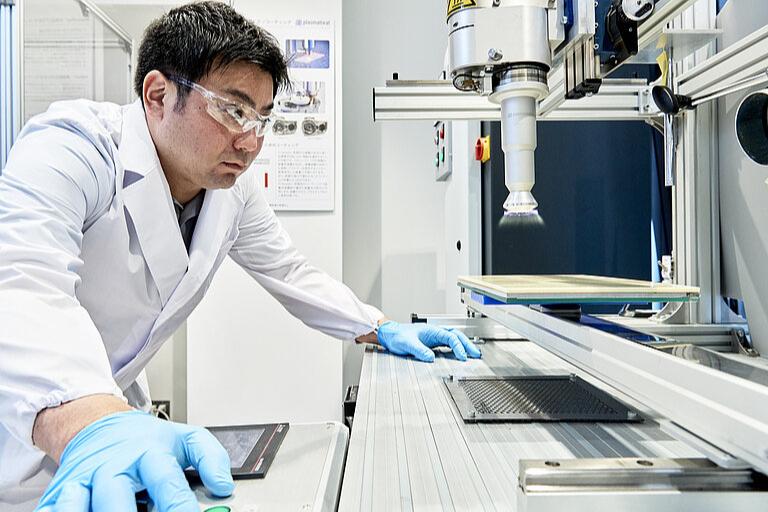

Openair-Plasma® generators – central control and management of plasma systems

Specially designed plasma generators are the basis of highly effective and energy-efficient pretreatment systems. We see the development of plasma jets and generators as a holistic task.

Plasmatreat generators are designed for simple, robust, and reliable complete systems with extensive control and diagnostic functions, such as double resonance systems, pulse-pause modulation, and wide voltage control based on state-of-the-art IGBT and Power-MOSFET semiconductor technologies.