-

Plasmatreat North America

-

Plasmatreat North America Overview

- Plasmatreat North America

- Sales Team

- Plasma as a Service

- FAQ

- Contact us

-

-

What is Plasma

-

What is Plasma Overview

- What is Plasma

- Plasma Processes

-

Plasma Surface Treatment

-

Plasma Surface Treatment Overview

- Plasma Surface Treatment

- Capability of Plasma

- Surface Activation

- Plasma Cleaning

-

Plasma Coating

-

Plasma Coating Overview

- Plasma Coating

- AntiCorr®

- PT-Print

- PT-Bond

- Functional Coating

- Plasma-SealTight®

- InMould-Plasma®

-

-

- Surface Determination

- FAQ

-

-

Industry Solutions

-

Industry Solutions Overview

- Industry Solutions

- Automotive

- Electronics

-

New Energies

-

New Energies Overview

- New Energies

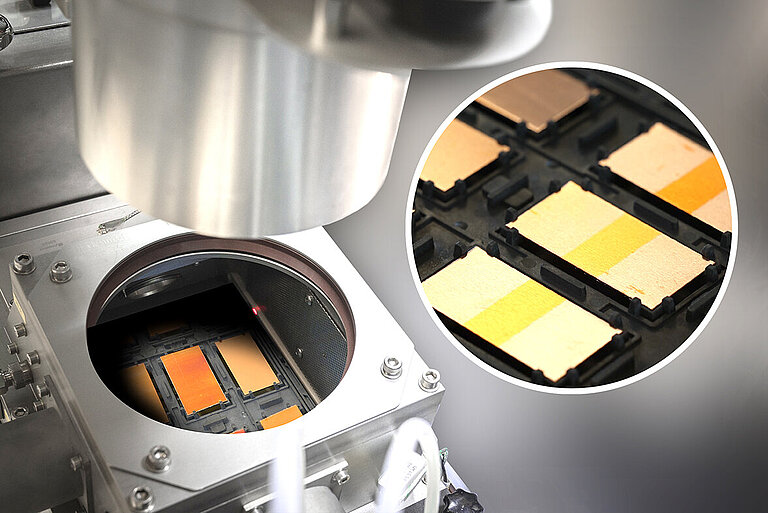

- Solar Technology

- Wind Power

- Energy Efficiency

-

-

Consumer Goods

-

Consumer Goods Overview

- Consumer Goods

- Furniture

- Appliances

- Toys for Children

- Sporting goods

- Eyewear

-

-

Packaging

-

Packaging Overview

- Packaging

- Plastic Packaging

- Board and Paper

- Glass-Metal Packages

-

-

Life Sciences

-

Life Sciences Overview

- Life Sciences

- Medical Technology

- Chemistry_Biochemistry

- Plasma Medicine

- Medical Disinfection

-

- Textiles

-

Transportation

-

Transportation Overview

- Transportation

- Aerospace

- Shipbuilding

- Trucks_Trailers_Mobile Homes

- Two Wheelers_Motorcycles

-

-

-

Processes

-

Processes Overview

- Processes

- Bonding

- Printing

- Painting

- 2-Component Injection Molding

-

-

Products and Services

-

Products and Services Overview

- Products and Services

-

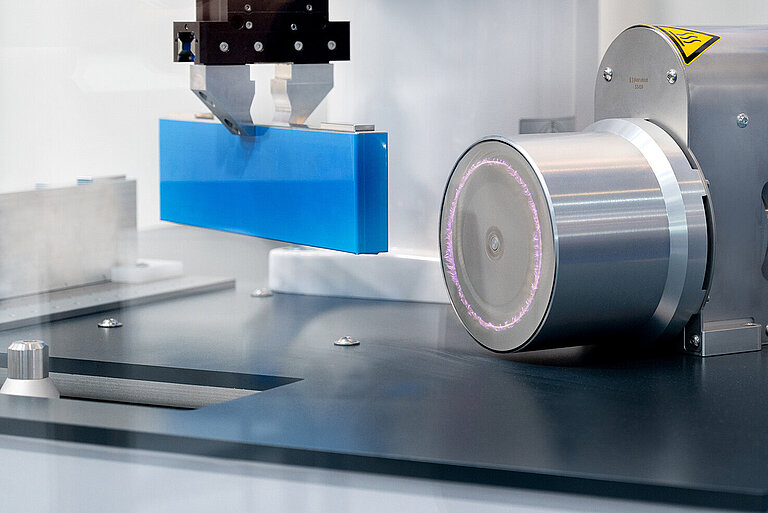

Openair-Plasma® Jets

-

Openair-Plasma® Jets Overview

- Openair-Plasma® Jets

- Static Jets PFW10 and PFW20

- Static Jet PFW70 and PFW100

- Rotary Jet RD1004

- Rotary Jet RD2004

- Rotary Jet RD2005

- Rotary Jet RD1010

-

- Openair-Plasma® Process Monitoring

- Openair-Plasma® Generators

-

Openair-Plasma® Systems

-

Openair-Plasma® Systems Overview

- Openair-Plasma® Systems

- Film and Foil Manufacturing

- Coil Coating

- Panel Treatment

- Profile Extrusion

- Robot Systems

-

-

Low Pressure Plasma Systems

-

Low Pressure Plasma Systems Overview

- Low Pressure Plasma Systems

- Aurora Standard

- Aurora Plus

- Aurora LC

-

-

Services for Surface Determination

-

Services for Surface Determination Overview

- Services for Surface Determination

- Test Ink Method

- Test Ink online order

- AntiCorr® Test Fluids online order

- Contact Angle Measurement - MSA

-

- Worldwide after-Sales Service

- Book a Demo

- Rent a system

- Contract Service

-

-

Company

-

Company Overview

- Company

-

About Plasmatreat

-

About Plasmatreat Overview

- About Plasmatreat

- Milestones

- Family Business

-

- Our Mission

- Innovations and Awards

-

Our Global Network

-

Our Global Network Overview

- Our Global Network

- Plasmatreat GmbH

- Plasmatreat SAS - France

- Plasmatreat North America

- Plasmatreat Trading (Shanghai) Co., Ltd.

- Plasmatreat GmbH - Turkey

- Plasmatreat Korea Ltd.

- Nihon Plasmatreat Inc. - Japan

- Plasmatreat Italia s.r.l.

- Plasmatreat Iberia S.L. - Spain

- Plasmatreat Asia Pacific Pte Ltd. - Singapore

- Plasmatreat (UK) Ltd.

- Plasmatreat Schweiz AG

-

- Research and Development

- Partners

-

-

Plasmatreat Academy

-

Plasmatreat Academy Overview

- Plasmatreat Academy

- Team

- Mission and Vision

- Facilities and Equipment

-

Online PlasmaTalks

-

Online PlasmaTalks Overview

- Online PlasmaTalks

- PlasmaTalks Archiv

-

- Seminars, Training Courses and Events

-

-

Press Area

-

Press Area Overview

- Press Area

- News and Press

-

- Trade Shows and Events

Choose your location:

-

Åland

Åland

-

Andorra

Andorra

-

Belgique

Belgique

-

BiH/БиХ

BiH/БиХ

-

Bulgaria

Bulgaria

-

Česko

Česko

-

Crna Gora

Crna Gora

-

Danmark

Danmark

-

Deutschland

Deutschland

-

Eesti

Eesti

-

Éire

Éire

-

España

España

-

Føroyar / Færøerne

Føroyar / Færøerne

-

France

France

-

Gibraltar

Gibraltar

-

Guernsey

Guernsey

-

Hrvatska

Hrvatska

-

Ísland

Ísland

-

Italia

Italia

-

Jersey

Jersey

-

Latvija

Latvija

-

Liechtenstein

Liechtenstein

-

Lietuva

Lietuva

-

Luxemburg

Luxemburg

-

Magyarország

Magyarország

-

Malta

Malta

-

Mann / Mannin

Mann / Mannin

-

Moldova

Moldova

-

Monaco

Monaco

-

Nederland

Nederland

-

Norge

Norge

-

Österreich

Österreich

-

Polska

Polska

-

Portugal

Portugal

-

România

România

-

San Marino

San Marino

-

Schweiz

Schweiz

-

Shqipëria

Shqipëria

-

Slovenija

Slovenija

-

Slovensko

Slovensko

-

Srbija

Srbija

-

Suomi

Suomi

-

Svalbard

Svalbard

-

Sverige

Sverige

-

United Kingdom

United Kingdom

-

Vaticano

Vaticano

-

Ελλάδα

Ελλάδα

-

Беларусь

Беларусь

-

Росси́я

Росси́я

-

Северна Македонија

Северна Македонија

-

Україна

Україна

-

Anguilla

Anguilla

-

Antigua and Barbuda

Antigua and Barbuda

-

Argentina

Argentina

-

Aruba

Aruba

-

Ayiti

Ayiti

-

Barbados

Barbados

-

Belize

Belize

-

Bermuda

Bermuda

-

Bolivia

Bolivia

-

Bonaire, Sint Eustatius en Saba

Bonaire, Sint Eustatius en Saba

-

Brasil

Brasil

-

British Virgin Islands

British Virgin Islands

-

Canada

Canada

-

Cayman Islands

Cayman Islands

-

Chile

Chile

-

Colombia

Colombia

-

Costa Rica

Costa Rica

-

Cuba

Cuba

-

Curaçao

Curaçao

-

Dominica

Dominica

-

Ecuador

Ecuador

-

El Salvador

El Salvador

-

Falkland Islands

Falkland Islands

-

Grenada

Grenada

-

Grønland

Grønland

-

Guadeloupe

Guadeloupe

-

Guatemala

Guatemala

-

Guyana

Guyana

-

Guyane française

Guyane française

-

Honduras

Honduras

-

Jamaica

Jamaica

-

Martinique

Martinique

-

México

México

-

Montserrat

Montserrat

-

Nicaragua

Nicaragua

-

Panamá

Panamá

-

Paraguay

Paraguay

-

Perú

Perú

-

Puerto Rico

Puerto Rico

-

Quisqueya

Quisqueya

-

Saint-Barthélemy

Saint-Barthélemy

-

Saint Kitts and Nevis

Saint Kitts and Nevis

-

Saint Lucia

Saint Lucia

-

Saint-Martin

Saint-Martin

-

Saint-Pierre-et-Miquelon

Saint-Pierre-et-Miquelon

-

Saint Vincent and the Grenadines

Saint Vincent and the Grenadines

-

Sint Maarten

Sint Maarten

-

Suriname

Suriname

-

The Bahamas

The Bahamas

-

Trinidad and Tobago

Trinidad and Tobago

-

Turks and Caicos Islands

Turks and Caicos Islands

-

United States

United States

-

Uruguay

Uruguay

-

US Virgin Islands

US Virgin Islands

-

Venezuela

Venezuela

-

한국

한국

-

북조선

북조선

-

Azərbaycan

Azərbaycan

-

British Indian Ocean Territory

British Indian Ocean Territory

-

Druk-Yul

Druk-Yul

-

India

India

-

Indonesia

Indonesia

-

Kâmpŭchea

Kâmpŭchea

-

Myanmar

Myanmar

-

O‘zbekiston

O‘zbekiston

-

Philippines

Philippines

-

Singapore

Singapore

-

Timor Lorosa'e

Timor Lorosa'e

-

Türkiye

Türkiye

-

Türkmenistan

Türkmenistan

-

Việt Nam

Việt Nam

-

Κύπρος / Kıbrıs

Κύπρος / Kıbrıs

-

Кыргызстан

Кыргызстан

-

Қазақстан /Казахстан

Қазақстан /Казахстан

-

Монгол Улс

Монгол Улс

-

Тоҷикистон

Тоҷикистон

-

საქართველო

საქართველო

-

Հայաստան

Հայաստան

-

ישראל

ישראל

-

أردنّ

أردنّ

-

افغانستان

افغانستان

-

الإمارات العربيّة المتّحدة

الإمارات العربيّة المتّحدة

-

البحري

البحري

-

السعودية

السعودية

-

العراق / عيَراق

العراق / عيَراق

-

الكويت

الكويت

-

اليمنية

اليمنية

-

ايران

ايران

-

پاکستان

پاکستان

-

دارالسلام

دارالسلام

-

سوري

سوري

-

عُمان

عُمان

-

فلسطين

فلسطين

-

قطر

قطر

-

لبنان

لبنان

-

مليسيا

مليسيا

-

ޖުމުހޫރިއްޔ

ޖުމުހޫރިއްޔ

-

नेपाल

नेपाल

-

বাংলাদেশ

বাংলাদেশ

-

ශ්රී ලංකා / இலங்கை

ශ්රී ලංකා / இலங்கை

-

ไทย

ไทย

-

ເມືອງລາວ

ເມືອງລາວ

-

中国

中国

-

中華

中華

-

日本

日本

-

澳門 / Macau

澳門 / Macau

-

香港

香港

-

Afrika-Borwa

Afrika-Borwa

-

Angola

Angola

-

Bénin

Bénin

-

Botswana

Botswana

-

Burkina

Burkina

-

Burundi

Burundi

-

Cabo Verde

Cabo Verde

-

Cameroun

Cameroun

-

Congo

Congo

-

Congo-Brazzaville

Congo-Brazzaville

-

Côte d’Ivoire

Côte d’Ivoire

-

eSwatini

eSwatini

-

Gabon

Gabon

-

Gambia

Gambia

-

Ghana

Ghana

-

Guinea Ecuatorial

Guinea Ecuatorial

-

Guiné-Bissau

Guiné-Bissau

-

Guinée

Guinée

-

Kenya

Kenya

-

Lesotho

Lesotho

-

Liberia

Liberia

-

Madagascar

Madagascar

-

Malawi

Malawi

-

Mali

Mali

-

Mauritius

Mauritius

-

Mayotte

Mayotte

-

Moçambique

Moçambique

-

Namibia

Namibia

-

Niger

Niger

-

Nigeria

Nigeria

-

République centrafricaine

République centrafricaine

-

Réunion

Réunion

-

Rwanda

Rwanda

-

Saint Helena, Ascension and Tristan da Cunha

Saint Helena, Ascension and Tristan da Cunha

-

São Tomé e Príncipe

São Tomé e Príncipe

-

Sénégal

Sénégal

-

Seychelles

Seychelles

-

Sierra Leone

Sierra Leone

-

Soomaaliya

Soomaaliya

-

South Sudan

South Sudan

-

Tanzania

Tanzania

-

Togo

Togo

-

Uganda

Uganda

-

Zambia

Zambia

-

Zimbabwe

Zimbabwe

-

اتحاد القمر

اتحاد القمر

-

التونسية

التونسية

-

الجزائ

الجزائ

-

السودان

السودان

-

الصحراء الغربي

الصحراء الغربي

-

المغربية

المغربية

-

الموريتانية

الموريتانية

-

تشاد / Tchad

تشاد / Tchad

-

جيبوتي /Djibouti

جيبوتي /Djibouti

-

ليبيا

ليبيا

-

مصر

مصر

-

ኢትዮጵያ

ኢትዮጵያ

-

ኤርትራ

ኤርትራ

-

Amerika Samoa

Amerika Samoa

-

Australia

Australia

-

Belau / Palau

Belau / Palau

-

Cocos (Keeling) Islands

Cocos (Keeling) Islands

-

Cook Islands

Cook Islands

-

Fiji / Viti

Fiji / Viti

-

Guåhån

Guåhån

-

Heard Island and McDonald Islands

Heard Island and McDonald Islands

-

Kiribati

Kiribati

-

Marshall Islands

Marshall Islands

-

Micronesia

Micronesia

-

Naoero

Naoero

-

New Zealand / Aotearoa

New Zealand / Aotearoa

-

Niue

Niue

-

Norfolk Island

Norfolk Island

-

Northern Marianas

Northern Marianas

-

Nouvelle-Calédonie

Nouvelle-Calédonie

-

Papua New Guinea / Papua Niugini

Papua New Guinea / Papua Niugini

-

Pitcairn Islands

Pitcairn Islands

-

Polynésie française

Polynésie française

-

Samoa

Samoa

-

Solomon Islands

Solomon Islands

-

Tokelau

Tokelau

-

Tonga

Tonga

-

Tuvalu

Tuvalu

-

Vanuatu

Vanuatu

-

Wallis and Futuna

Wallis and Futuna

Company News

Company News

Company News

Exhibitions