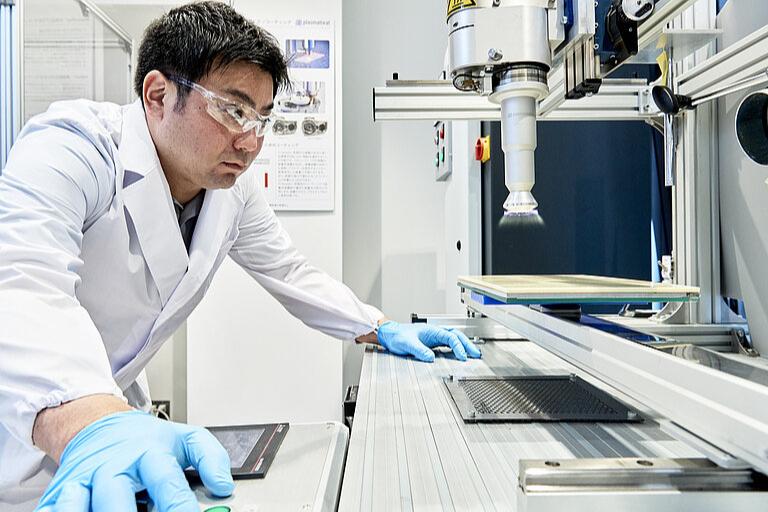

Openair-Plasma® Process Monitoring

With more than 99% availability, Openair-Plasma® systems offer our Plasmatreat customers the greatest process capability. Openair-Plasma® jets can also be equipped with threefold process monitoring in order to respond quickly and effectively and prevent a system outage.

For the Greatest Process Capability

Optical Monitoring/Management: To ensure uniformly high plasma quality, the emergent plasma stream is spectrally monitored on a continuous basis. A sensor integrated into the plasma jet measures the light emitted by the plasma as part of a one-channel optical detection system. This is followed by a permanent amplitude evaluation in the relevant spectral range of the emitted light. This monitoring is independent of plasma generation and reliably describes the process parameters of the plasma.

Movement Controls / Monitoring: Along with plasma intensity and effective distance, the travel and rotation speed of the plasma jets is an important criterion of treatment quality. The movement control systems available in Plasmatreat systems ensure reliable process runs and high production process reliability.

Controlling the Media Supply: Control of the supply of media is indispensable to ensure reproducible process-specific plasma parameters (temperature and intensity). Plasmatreat offers monitoring units for every need, including a flow measuring device controlled by a micro-controller.

Industry 4.0-ready – for digitalized manufacturing processes

Reproducible process sequences, high system reliability, low manufacturing tolerances, robust standards of quality and data-supported automation – these specifications can only be achieved with targeted process control. Plasmatreat supports digitalized production processes and supplies the necessary system components with open, interoperable, flexible connections based on standardized state-of-the-art technologies.

The plasma control unit (PCU) is designed to control and monitor a plasma jet. Process data are transmitted via EtherCAT / CANopen: The PCU is connected to the generator via CANopen. Other cables are used for control purposes and to transfer energy to the plasma jet. The integrated transformer (HTR) provides the high-voltage requires to operate the jet.

Modular configuration

Each electronic assembly (PCU) can operate one stationary and one rotary jet. The double PCU is required to operate the double rotary jet. Up to four PCUs or two double PCUs can be connected in series, depending on the type and number of plasma jets required.

This allows a modular setup in which the individual plasma jet can still be operated and controlled separately (Plasma Switch Automatic – PSA).

PCU control functions

- Control of process gas flow (Flow Control Module - FCM)

- Dynamic pressure measurement (Pressure Control Module - PCM)

- Motor speed-current-voltage control (Rotation Control Module - RCM)

- Optional: Plasma power control

Monitoring functions

- Visual inspection of the plasma (Light Control Module – LCM)

- Control of plasma power / measurement of HTR output (Plasma Power Measurement – PPM)

- Control of flow of process gas to the jet (Flow Control Module – FCM)

- Rotation monitoring (Rotation Control Module – RCM)

- Dynamic pressure monitoring (Pressure Control Module – PCM)